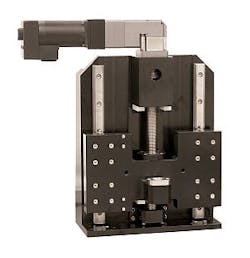

The VTS300 vertical translation stage can position loads up to 450 kg with ±25 μm accuracy and provides travel from 50 to 200 mm. The base and table are made from a high-stiffness aluminum alloy. Preloaded angular-contact ball bearings support the 0.1 in./rev lead-screw. Motors can be left, right, or rear

oriented.

Aerotech

Pittsburgh, PA

www.aerotech.com

-----

PRESS RELEASE

VTS300 Vertical Translation Stage Positions

Extreme Loads With 0.064 µm Resolution

Extreme load carrying capability (up to 450 kg) in a compact package

Resolution to 0.064 μm

Lead screw does not back-drive which allows “set and forget” operation

±10 µm bi-directional repeatability and ±25 µm accuracy

Vacuum compatible

The Aerotech VTS300 vertical translation stage can position loads up to 450 kg (1000 lb) with ±25 µm accuracy in applications requiring a compact footprint with travels from 50 to 200 mm. Applications range from step and settle placement to high force generation. Multiple units can be combined for lift and tip/tilt motion to provide a flexible, high performance, multi-axis motion solution.

Design and Construction Features

The VTS300 series incorporates the highest quality components to provide superior positioning performance over a long service life. From the special high-stiffness aluminum-alloy base and table, to pre-loaded angular contact ball-bearings that support the 0.1 inch/rev lead-screw, each component of the VTS300 was chosen for use in applications requiring precision motion with extremely high loads. Linear motion guide bearings give excellent payload capability and long life, even with heavy offset loads, as well as outstanding accuracy, flatness, and straightness over the full travel range.

VTS300 series stages are offered with matched stepping or NEMA 23 or 34 brushless servomotors that drive a high capacity 90° gearbox. Motors can be left-, right-, or rear-oriented to meet your requirements.

Options Include Adjustable Travel and Vacuum Preparation for 10-6 torr

In addition to movable limit switches to adjust travel range, vacuum preparation is available for operation in vacuum chambers from 10-3 to 10-6 torr. Aerotech is also a recognized expert in the design and manufacture of complete custom motion systems and would be happy to discuss a system tailored to your specific application.

For further information, please contact Steve McLane at 412-967-6854 (direct), or via e-mail at [email protected].

The VTS300 series data sheet is available at:

http://www.aerotech.com/products/liftstages/vts300.html

-----

Subscribe now to Laser Focus World magazine; it's free!