Christopher Chow, Jim Bucklew, Dan Miller, and Todd Cleavenger

Walking down the aisles of a store, one is amazed at how consumer products have been expanding in features while shrinking in size. Gone are the bulky computer monitors and the projection TV sets. In their places are the ever-thinner LCD and plasma displays. Also the 3G smart phones cram features, including web news, e-mails, games, videos, songs, camera, and, oh yes, phone messages into a very small package. The fact is that engineering ingenuity has allowed the packing of a long list of functionality into simple multi-layer components.

The multi-touch panel, made famous by the iPhone, consists of at least 10 layers of material enabling the capacitive signals for the gesturing features, all within a thickness of 1 mm. In medical products, blood-glucose monitoring strips consist of laminated layers of material that function for blood receiving, fluid transport, enzyme reaction, color indicating, and glucose measuring. Even the flexible bag that keeps snacks fresh on the shelf consists of 0.075 mm-thick high-performance coextruded film that includes a graphical printed layer, an oxygen barrier layer, a moisture barrier layer, a structural layer, and a sealing layer. As the material structures become more complex, the sophistication of using lasers to process these materials also increases.

When a focused laser beam is concentrated on a target of tens of microns or less in diameter, the laser/material interactions at the target area will be highly dependent on the absorption of the material at the specific laser wavelength, the peak power density of the laser, and the duration of the exposure to the irradiation. Photo-electronic or photo-thermal bond breakage will take place in a combination of events with a time sequence specific to the composition of the irradiated material. Less absorptive material will require longer laser dwell time within which the material will experience conductive heat transfer, material stress, melting before re-solidification or surface evaporation, or burning before charring. For highly absorptive material, material evaporation or particle ablation will happen at a very short time. In its extreme case, explosive phase-change or plasma-formation take place, creating a directional shock wave of the evaporated material. The action of laser processing, in the form of cutting, scoring, drilling, welding, and so on, are manifestations of some or all of these interactions.

For multi-layer material, the easiest method of preferential laser processing on a specific layer is to select a laser wavelength where that layer has substantially higher absorption. A typical example is the blind micro-via drilling of polyimide laminated to copper foil for flexible circuits. Because polyimide absorbs relatively well at the 9.4 micron CO2 laser wavelength while copper is highly reflective, blind micro-via can be readily achieved because the layer-to-layer boundaries between polyimide and copper act as the predetermined endpoints.

Preferential laser cutting on multi-layer polymeric material follows a similar principle, but careful considerations must be taken into account for the properties of each of the polymers and the precise controls of the laser system. To a large degree, most of the organic materials absorb in the mid-infrared spectrum. This is why CO2 lasers, operating in a wavelength range from 8 to 11 microns and a wide range of power outputs, are among the most useful lasers for processing polymeric material. In practice, each layer within a multi-layer film is relatively thin, typically from less than 5 microns to 75 microns. Depending on the absorption coefficient of a specific layer, laser energy could partially pass through one layer to the other, resulting in through-cut of the complete structure. How then can we selectively process multi-layer organic materials? The solution involves understanding the differential absorption of the layers, and it also involves selecting the right laser system with precise control of the power, pulsing conditions, and focusing optics as well as the coordinated motions by which laser power is delivered.

Applications

One of the laser applications on polymeric film is the creation of easy-open consumer packages. The earliest adapter was the high-performance polyester/polyethylene (PET/PE) flexible packaging film. Polyester is dimensionally stable, printable, and capable of producing premium quality images with high-impact graphics, while polyethylene provides the structural and sealing properties required for bag making. Barrier films for oxygen and moisture can be added in between the PET and PE to preserve the contents in the package. Because PET has a much higher absorption coefficient (152 cm-1) than polyethylene (13 cm-1) at the 10.6 micron laser wavelength, laser cutting of the polyester layer is readily achieved without physically degrading the tensile strength of the polyethylene. In fact, due to the relative transparency of the polyethylene to the CO2 laser, PET can be laser cut through the polyethylene side and still preserve the structural characteristics of the polyethylene.

Lasers continue to provide innovative applications for the PET/PE film. Recently, microwave-ready packages have been developed that have predetermined “vent” points created by a laser that, when heated, will burst and allow the steam to escape. This requires a much more precise deep scoring of the film. In production, the film can be laser processed at 300 m/minute. Precise power control with ramp-up and ramp-down consistency can be easily achieved with minimal waste.

Innovative manipulation of laser energy, coupled with an understanding of material absorption in processing multi-layer polymeric material will lead to many new applications, due to the virtually unlimited combination of organic and polymeric compounds available. For example, in a polyester/ethylene vinyl alcohol/polyethylene (PET/EVOH/PE) combination, micro-channels in the EVOH layer can be produced under proper exposure of laser energy to an otherwise unaffected film. This is due to the fact that EVOH has a very high absorption coefficient (above 400 cm-1) compared to PET and PE. Experiments based on this and other similar observations are being explored for potential industrial applications.

Polypropylene on polyethylene (PP/PE) is also a popular packaging film. Despite the close absorption coefficients of 32 cm-1 and 13 cm-1 at 10.6 micron CO2 laser wavelength, respectively, between the two polymers, partial scoring on polypropylene is still possible by proper focusing of the laser beam on the surface of the PP and precise control of the laser energy at all times. Depending on the speed of the beam in contact with the film, a portion of the molten PP material at the wings of the laser beam can re-solidify before reaching evaporating temperature, leaving a build-up of material as a ridge along the score line. This phenomenon adds to the physical effect of directional tear along the scored line.

In processing multi-layer polymeric material, management of the heat dissipation from any absorptive layer is particularly important because most polymers have comparatively low melting points. When the laser beam is absorbed, its energy is transferred to the absorbing layer primarily as heat. If this heat is not properly utilized before thermal conduction within the material takes place, it can propagate and subsequently melt the adjacent layer. This can be an advantage or disadvantage, depending on the specific application. In the case where partial cutting is desired, evaporation of the molten material from the surface ideally occurs before the heat conduction sets in. Therefore, subjecting the material to a higher laser power at higher processing speed frequently yields better results. Conversely, highly absorptive layers can be intentionally incorporated into the multi-layer structure to enhance the cutting of the otherwise non-reactive material. Take the case of some metalized PET/PE constructions. CO2 lasers are often ineffective when cutting from the metalized side because the metallic layer is highly reflective to the laser wavelength. However, when the laser beam is passed through the polyethylene and absorbed by the PET layer, both the PET and the metalized layer can be scored easily in a clean and efficient manner.

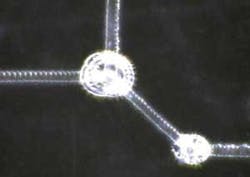

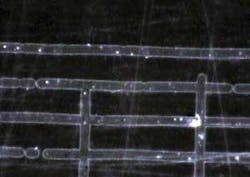

Choosing the right laser wavelength, pulse energy, and pulse width for an application is paramount. This is best illustrated by the laser patterning of transparent conductive electrodes such as indium tin oxide (ITO) on a polyester substrate. Of significant concern are defects caused by the thermal effects of laser processing, particularly damage to the substrate and roughened ITO edges, when using wavelengths such as 1.06 micron. Switching to the shorter 355 nm laser wavelength, these damages are minimized but may still occur where the etched trace lines overlap (see FIGURE 1). Thermal damage to the substrate can manifest as a microscopic “well-up” of the substrate along the edge of the etching path, leaving a protrusion and lifting the ITO above the rest of the PET surface. These effects occur when neither the peak pulse power nor the repetition rate of the laser pulse trains ablate the ITO fast enough to avoid the thermal build-up. The advent of highly pulsed fiber lasers operated at high repetition rates (in excess of 150 kHz) allows for the rapid processing of ITO at linear speeds on the order of hundreds of centimeters per second. The process is sufficiently fast to avoid thermal damages adjacent to the ablated area (see FIGURE 2). ITO etching can now be performed with a 1.06 micron pulsed fiber laser or its harmonic at 533 nm with excellent results. With these improvements, laser etching of ITO on PET will find rapid utilization in the formation of electrodes for touch screen and display, or for electrical isolation during the production of thin-film solar cells.As stated, the precise laser processing of thin multi-layer material requires complete control of the laser system and handling of the material during each and every processing step. This requires a thorough understanding of the laser source and the material properties, as well as sophisticated engineering to coordinate all the motions necessary for transporting the material, steering and focusing the laser beam, and locating the pattern on the part within tight tolerances. Various systems are available utilizing different classes of lasers from CO2 to fiber lasers to UV lasers to suit specific applications. Visit www.youtube.com/precoinc to view high-speed laser processing.

Lasers are now an integral part of modern society, providing extraordinary opportunities for innovation in an ever-widening range of materials processing and manufacturing applications. Understanding the interactions between materials and lasers allows us to maximize the potential of these opportunities.

Dr. Christopher Chow is executive vice president, Jim Bucklew, Dan Miller, and Todd Cleavenger are applications development engineers at Preco Incorporated (Somerset, WI; www.precoinc.com).