Cladding is a well-established process for improving the wear and corrosion resistance of metal parts. While traditional arc welding and laser-based methods are economically viable processes that deliver excellent results, there is a risk of carbide grain formation during the cladding process, which can compromise the mechanical strength and lifetime of the cladding. This article reviews a new automated, laser-based process that avoids grain formation, and explores how the process has been enabled by a new generation of fiber lasers that are immune to back-reflections.

Traditional laser cladding characteristics

The methods and benefits of laser cladding have been described in this magazine several times in the past [1, 2]. Briefly, the cladding material is introduced onto the part surface in powder or wire form, and the laser is used to selectively melt this material, as well as the substrate, to a very small depth in order to fuse the two.

Laser cladding delivers several advantages over arc welding and thermal spraying methods. Specifically, precise, limited application of heat results in minimal or no heat distortion in the part, eliminating the need for subsequent post-process machining. Laser cladding also produces very little mixing between the deposited and substrate materials (dilution), and yields a strong, truly metallurgic bond between the clad layer and substrate.

However, several researchers have noted that the rapid material cooling that occurs during laser cladding sometimes produces bonding defects and some porosity in the clad layer, and can lead to the formation of grains or other heterogeneous microstructures [3-6]. The specific nature of these structures is highly dependent upon the exact laser processing parameters and cladding materials employed, and have been observed to include cracks, pores, and a variety of columnar and banded grain structures. Each of these structures can limit the lifetime and effectiveness of the cladding. For example, cladding cracks offer sites for corrosion to occur, and may even provide a path through the clad layer to the substrate itself. Grains or other microstructures affect the mechanical properties of the clad layer, and have proven in some cases to reduce clad tensile strength.

Optimized cladding

The effect of various process parameters such as laser power, laser beam scanning speed and material feed rate, and the precise recipe of cladding material have been studied and characterized in some detail. By properly controlling these factors, the formation of undesirable clad microstructures can be minimized or eliminated in a deterministic manner. Specifically, it is possible to create a system for high-performance cladding by accurately modeling the cladding process, optimizing the materials employed, and then carefully controlling the cladding process to replicate the calculated results.

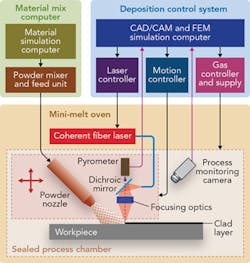

Köthener Spezialdichtungen GmbH (KSD; Kleinwülknitz, Germany) has developed such a system, which they call the Rapid Laser Materials Manufacturing system (R:LM2). The system consists of three main functional elements, namely a material mix system, a mini-melt oven, and a deposition control system (FIGURE 1).

The material mix system includes several different cladding powders as well as a computer equipped with material simulation software. The mini-melt oven includes a fiber laser and a sealed process chamber containing focusing optics, a powder delivery nozzle, a motion system, a pyrometer, and a process monitoring camera. The deposition control system has a computer running CAD/CAM software and finite element method (FEM) simulation software.

The R:LM2 exploits the fact that a large variety of different claddings can be created by combining a limited set of metal powders. To choose the right set for a given application, the customer's requirements in terms of desired clad mechanical and chemical (e.g., corrosion resistance) characteristics are input to the system. Then, the material simulation program uses phase diagrams to calculate the optimum combination of available clad materials that address the performance requirements.

The FEM simulation software in the deposition control system then takes this recipe and determines the cladding parameters, including powder feed rate, laser power, gas composition, and process temperature necessary to achieve optimum results. Within the sealed process chamber, the metal powder is sprayed onto the workpiece through a nozzle and then melted by the laser. The exact shape of the clad area is defined by the movement of the nozzle and laser beam, which is controlled by the CAD/CAM software in the deposition control system. The deposition control system monitors the size and location of clad area with the process camera, as well as the process temperature using the pyrometer, and adjusts the parameters as necessary to achieve the desired results. The R:LM2 also closely controls the gas atmosphere within the process chamber. This is critical to delivering homogenous and reproducible cladding.

Clads produced by the R:LM2 exhibit dramatically finer carbide grain structure than traditional laser clads. These coatings are free of pores or cracks, and can reach hardness levels of 68 HRC. In addition, the system also offers the potential to significantly reduce cladding cost because the most common traditional cladding materials, including nickel alloys, tungsten carbides, and Inconels, are all expensive. But the sophisticated modeling and precision deposition capabilities of the R:LM2 enable it to achieve the same results, in terms of clad corrosion and wear resistance, using combinations of less costly ferrous alloys. Plus, the system substantially reduces cycle times for fabricating complex parts.

Fiber laser considerations

Fiber lasers are a good match for the requirements of the R:LM2 process because they offer the necessary high power output (around 800W) and near-infrared (NIR) wavelengths, but with lower cost of operation and much longer service intervals than other laser types, such as flash lamp-pumped Nd:YAG.

With first-generation fiber lasers based on single-emitter laser diode pumps, all the numerous pump components are typically fused together to maximize stability. While this approach is generally robust, it is particularly susceptible to damage by back-reflections from the target material. Thus, some type of optical isolator must be used when processing reflective metals, such as copper and brass. Also, the use of fused components (sometimes including the final delivery fiber) means these lasers are not field-serviceable. So, if any components are even slightly damaged, the entire laser must be shipped back to the factory and replaced.

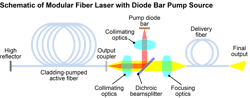

Coherent's novel modular approach to fiber laser design is based on the use of diode laser bars, rather than single emitters, as the pump sources. The light from these pump bars is introduced into the gain fiber using a beam combiner consisting of discrete optical elements. This same beam combiner collimates the output from the gain fiber, and other optics efficiently couple this into the final delivery fiber.

The geometry of the beam combiner prevents back-reflections from reaching the pump diode laser bars. Together with the absence of damage-prone splices, this makes this design immune to damage from back-reflections (FIGURE 2).The modular approach also allows both field serviceability and flexibility because it enables the end user to exchange the delivery fiber in a matter of minutes. Moreover, the other modular components, such as the pump diode bar and even the gain fiber, can all be field-replaced if necessary.

After having reliability problems using a traditional architecture fiber laser, KSD switched to the HighLight 1000FL 1kW fiber laser from Coherent. This eliminated the operating difficulties they had experienced in their process because of back-reflections.

Applications

Currently, KSD GmbH is employing the R:LM2 process in the production cladding of gaskets for industrial faucets, and for the bearing surfaces of races in sliding rings or rotary feedthroughs (FIGURE 3). Such sealing components are used in rotary pumps, immersion pumps, or screw feeders. The gaskets used in safety or control fittings have to withstand extreme forces, such as cavitation pitting or fluid flow wear. They are operated in temperatures ranging from -255° to 650°C, and are utilized with abrasive media at stroke rates of >100,000 per year. The bearing race surfaces need to operate at a travel rates of 400,000 km/year in conjunction with highly viscous media having abrasive or adhesive properties. To date, the clads produced using the R:LM2 process from entirely ferrous alloys have proven effective in these applications.KSD is also developing applications for laser additive manufacturing of three dimensional parts using R:LM2 technology. Typically, the process starts with the deposition of a relatively thin (600μm) layer of material in several strips on the wall of the part. Then, the seams between these strips are filled in a second pass.

The powder utilization in this process is 70–80%, and the final part dimensional accuracy is in the 0.2–0.3mm range. This dimensional accuracy is a factor of about 10 lower than with traditional powder bed methods, but—like selective laser melting—final part dimensions can be rapidly obtained with mechanical post-processing. In this case, the unique advantage of the R:LM2 method is that a variety of materials can be processed and be deposited with high flexibility using the material mix computer.

In conclusion, a new, automated system for laser cladding simplifies the process and makes it more economical by enabling it to use less costly, ferrous alloys. Together with a fiber laser source that is immune to back-reflection damage and is also easier to service, this should help to make laser cladding and laser additive manufacturing accessible to a broader audience.

REFERENCES

1. V. Malin and S. Woods, "Efficient high-power diode laser cladding," Industrial Laser Solutions (Aug. 2009).

2. K. Parker, "Higher output power and customized beam shapes substantially improve heat treating and cladding," Industrial Laser Solutions (Jul/Aug. 2012).

3. S. Zhou, Y. Huang, X. Zeng, and Q. Hu, Mat. Sci. Eng. A-Struct., 480, 1–2, 564–572 (May 2008).

4. V. Ocelík, I. Furár, and J. De Hosson, Acta Mater., 58, 20, 6763–6772 (Dec. 2010).

5. L. Parimia, G. Ravi, D. Clark, and M. Attallah, Mater. Charact., 89, 102–111 (Mar. 2014).

6. T. Abioye, D. McCartney, and A. Clare, J. Mater. Process. Tech., 217, 232–240 (Mar. 2015).