Experience from decades of industrial laser applications, along with vertical integration leading to better components and materials, have enabled laser manufacturers to build scientific lasers with industrial reliability. At Coherent (Santa Clara, CA), investment in an immersive reliability concept called HALT/HASS long used in other reliability-critical industries has assisted in achieving this goal (HALT stands for highly accelerated life testing and HASS stands for highly accelerated stress screening). For example, in a 2014 Laser Focus World article entitled “Ultrafast scientific lasers undergo an industrial revolution,” Coherent noted that a one-box femtosecond oscillator was delivering levels of reliability that opened the path towards significant advances in data productivity.

Six years is a long time in a dynamic field like ultrafast lasers, so now seems like a reasonable time to assess if and how this industrial revolution has progressed, and more importantly, how it has impacted real scientific studies. This second article on the topic focuses on the more complex and challenging domain of femtosecond amplifiers.

Titanium sapphire vs. ytterbium

For many years, titanium sapphire (Ti:sapphire) was the gain material of choice in virtually every ultrafast amplifier and oscillator. Today, however, ytterbium (Yb)-doped crystals or fibers are well-established alternatives to Ti:sapphire and complement its performance capabilities. Ytterbium has the advantages of being directly and efficiently pumped by laser diodes, resulting in a smaller quantum defect than Ti:sapphire. As a result, Yb lends itself to more-compact platforms.

From an applications viewpoint, the important differences are power, pulse energy, and repetition rates. Ti:sapphire amplifiers are unmatched in their ability to deliver high pulse energy. Coupled with the short pulses (less than 35 fs) of turnkey Ti:sapphire amplifiers, this translates into peak powers approaching the terawatt level. These amplifiers are therefore favored for applications requiring high fluence such as strong-field physics and high harmonic generation (HHG) for extreme ultraviolet (EUV) or attosecond-pulse generation.

The optimum performance of one-box Ti:sapphire amplifiers is at low repetition rates: 1–10 kHz. Ytterbium amplifiers, on the other hand, have lower pulse energy, but deliver much-higher average power (tens of watts) with extremely flexible repetition rates up to the megahertz regime. As a result, Yb amplifiers are optimum for applications requiring fast data collection with modest energy requirement (such as imaging and solid-state spectroscopy) or where high average power is critical (such as materials processing). Moreover, as a newer material, Yb amplifiers have more room for performance improvements.

This article will examine four applications, three scientific and one industrial, that highlight the impact of the “industrial revolution” on day-to-day performance, reliability, and productivity—either in terms of data or process throughput.

Meeting a thermal-stability challenge

Ferroelectric materials and films can support a permanent electric dipole (meaning electrically polarized), which is why they are already widely used in electronic and photonic devices. However, more-detailed information is needed on films as thin as a few unit cells, as these could support higher density electronics and also offer the potential of custom (atomic-scale) novel ferroelectric heterostructures. A group led by Dr. Morgan Trassin and Prof. Manfred Fiebig at ETH Zurich (Switzerland) has been conducting the first in situ measurements of film polarity during the actual growth process performed by pulsed laser deposition with an excimer laser (Coherent LPX 220).

In any material where there is a break in symmetry and long-range order, irradiating with intense laser light can result in some second-harmonic generation (SHG). This effect has already been used in the past as a diagnostic with thicker ferroelectric samples. However, no one had previously demonstrated in situ harmonic generation (ISHG) during the film growth process.

“SHG is highly sensitive to polarization,” says Trassin. “So, we reasoned that we could use the polarization dependence of the SHG signal to map the alignment of domains in a ferroelectric film. And, more importantly, we wanted to investigate the potential of ISHG to follow the polarization (or depolarization) of ultrathin films during the epitaxial deposition process.” The light source for their SHG setup is a Ti:sapphire one-box amplifier (Coherent Astrella) that pumps a tunable optical parametric amplifier (OPA).

The technique has proved successful and has been capable of measuring ferroelectric polarization properties, as films are grown from zero to just a few unit cells in thickness. Based on this success, the Trassin group has applied this technique to examine the local polarization orientation, as the layers are incorporated into heterostructure model devices.

What is the impact of “industrial reliability”? “The stability of this amplifier to changes in ambient temperature is particularly important to our work,” says Trassin. “We grow these films in a deposition chamber with internal temperatures up to 950°C, so the temperature of our lab unavoidably varies considerably during the day (see Fig. 1). But critical amplifier output (pointing and power) parameters are thankfully unaffected.”

Multiday data acquisitions: 2D spectroscopy

2D spectroscopy involves measuring an optical signal as a function of pulses with two different optical frequencies and provides a wealth of data that would be impossible to obtain by any other method. The signal can be based on various different processes, including absorption, Raman, and sum/difference frequency generation. The data can be presented as two-dimensional contour graphs plotted against two frequencies, but are usually recorded as time-domain data and then Fourier-transformed in the frequency space. To ensure coherence, the three (or four) different femtosecond pulses required for these measurements are generated from a single source using a pulse shaper in what is essentially a four-wave mixing effect in the sample. The very wide spectral bandwidth of the short Ti:sapphire pulses critically enables a wide frequency range to be covered in a single set of data.

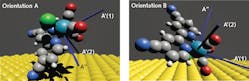

A group led by Professor Wei Xiong at the University of California, San Diego has recently used 2D spectroscopy to investigate a heterogeneous CO2 reduction catalyst, Re(diCN-bpy)(CO)3Cl, bound as a monolayer on gold surfaces. The researchers have performed experiments based on sum-frequency generation (SFG), a technique originally developed by Xiong as a graduate student in the lab of Martin Zanni. SFG vibrational signals are only generated at surfaces and phase interfaces. So, comparison with 2D spectra of the unbound catalyst (that is, in solution) enabled the Xiong group to reveal how the catalyst is bound to gold (see Fig. 2) and how its bond structure is impacted by this.Xiong cites the operational simplicity of their one-box industrialized amplifier (Coherent Astrella) as a key benefit in these inherently challenging experiments. Just as important is the long-term stability: some of their time-resolved experiments (i.e., 3DSFG) require data runs in excess of 40 hours, during which the amplifier output must remain perfectly stable.

Neuroscience: 3P-microscopy, photostimulation, and photoablation

Two-photon microscopy and related techniques represent a major market segment for one-box oscillators, particularly in neuroscience, and now one-box Yb amplifiers are starting to enable new neuroscience applications. The main applications here are three-photon (3P) microscopy, photostimulation of groups of neurons, and photoablation of select neurons. These all require one or more of the main Yb amplifier advantages: long output wavelength, high repetition rate, and high average power. For example, high power is needed for two-photon photostimulation of hundreds of neurons using optogenetic expression. The power requirement stems from the large number of cells to be stimulated simultaneously, as well as system losses in spatial light modulators (SLMs).

Three-photon microscopy is a relatively new technique that depends on the simultaneous absorption of three photons, a low-probability event that therefore requires the high photon flux from an amplifier rather than an ultrafast oscillator. As a scanning-imaging application, high repetition rate is also necessary to acquire many pixels. Here, a Yb amplifier is usually combined with a tunable OPA to deliver high power in the 1.3 and 1.7 μm wavelength windows that yield deeper penetration into brain and other scattering tissues.

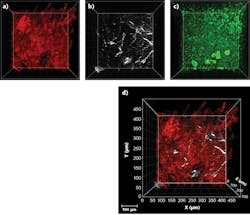

Professor Raluca Niesner at the German Rheumatism Research Center (DFRZ; Berlin, Germany) recently used a Yb amplifier (Coherent Monaco) together with an OPA (Coherent Opera-F) to perform 3P imaging inside lymph nodes. These are densely packed with cells, which causes scattering issues for two-photon microscopy.

“One of the targets of my research group is improved understanding of the rogue inflammatory response that results in rheumatoid arthritis in particular, and in chronic inflammatory diseases in general,” says Niesner. Preliminary studies of mouse-limb lymph nodes by Dr. Rakhymzhan in Niesner’s laboratory indicate that 3P excitation can deliver a dramatic increase in deep imaging capabilities, specifically a greater-than 2X increase in maximum imaging depth for 3P vs. 2P under identical conditions. Figure 3 shows typical images.Precision metal cutting of medical devices

Surely nothing illustrates the success of the industrialization of scientific ultrafast lasers more than the use of the same laser in both scientific and industrial applications. Bringing the story full circle, a brief look is taken at an industrial application that illustrates both the flexibility of Yb amplifiers and the broad benefits of the “industrial revolution” approach to scientific and commercial applications.

Lasers with ultrashort pulse durations have long been used in micromachining (cutting, drilling, scribing, and so on) because the short pulse duration minimizes the heat-affected zone (HAZ)—the extent of surrounding material that exhibits undesirable thermal damage such as melting/resolidification or microcracking. The HAZ is minimized when the pulse duration is short compared to the thermal diffusion time in the target material, so that most of the extra heat associated with the cutting or drilling process is carried away in the ejected debris before it has time to spread into the surrounding material.

Until recently, ultrashort-pulse (USP) industrial lasers have been mostly confined to the picosecond domain, limited by the bandwidth of the neodymium (Nd)-doped gain medium. However, for some applications, even the small HAZ from picosecond lasers was problematic, indicating a need for even shorter pulse durations. Unfortunately, femtosecond amplifiers based on Ti:sapphire do not have the requisite combination of high repetition rates and high average power. The advent of Yb femtosecond amplifiers with output powers up to 60 W has thus completely changed this situation. One of the first applications to benefit has been medical device fabrication.

A standout example can be found at Motion Dynamics (Fruitport, MI), a manufacturer of “difficult” subassemblies for the medical market such as steerable catheter products for neurovascular interventions. They use a four-axis cutting machine (Coherent StarCut Tube) equipped with a Monaco femtosecond amplifier rated at 60 W (see Fig. 4). Chris Witham, President of Motion Dynamics says, “Our products require cutting and drilling a range of different metals, including gold, where surface roughness and edge quality are critical qualities. The femtosecond laser enables us to fabricate these components in a single step, typically with no polishing or other postprocessing required.”The success of the “industrial revolution” in ultrafast science has been clearly demonstrated in these, and many other, representative applications that are critically enabled by the reliability and stability resulting from this design and manufacturing approach.